GAC Trumpchi employs robotic arms for precise car seat installation.

GAC Trumpchi is revolutionizing car manufacturing by employing robotic arms for car seat installation, enhancing precision and efficiency in automotive assembly. This innovative approach to GAC Trumpchi car seats leverages advanced robotics to automate car seat fitting, significantly improving the quality and speed of production. The blog post explores the role of robotic arms in automotive assembly, highlighting the advantages of automated car seat installation, such as reduced labor costs and enhanced accuracy. GAC Trumpchi’s high-tech manufacturing process exemplifies cutting-edge automotive robotics, especially in vehicle interior assembly. As the industry continues to evolve, the article delves into future trends in robotic car seat installation, emphasizing the ongoing innovations in automotive robotics that promise to further transform vehicle manufacturing and assembly practices.

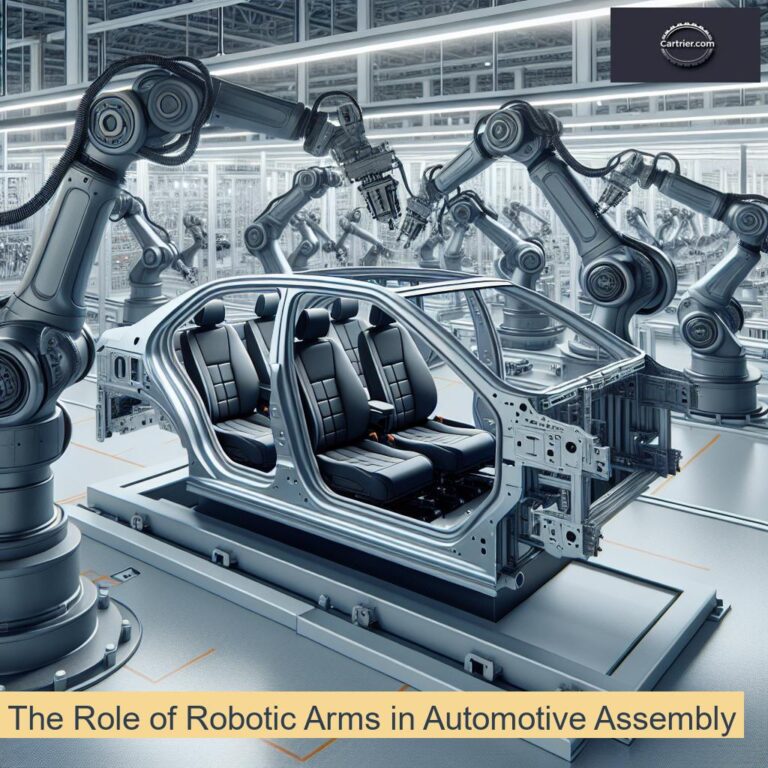

The Role of Robotic Arms in Automotive Assembly

The integration of robotic arms within the automotive industry significantly enhances the assembly process. One of the standout examples is GAC Trumpchi, which employs advanced robotic technology for the precise installation of car seats. This innovation not only boosts efficiency but also improves the overall quality of GAC Trumpchi car seats, demonstrating the transformative capabilities of robotics in manufacturing.

With the increasing demand for higher production rates and quality assurance, automation in car seat installation has become essential. Robotic car seat installation systems ensure that each component is fitted accurately and consistently, reducing variability that can occur in manual processes. The use of robotics in automotive manufacturing leads to enhanced productivity and safety, ultimately benefiting both the manufacturer and the end consumer.

Key Functions of Robotic Arms

- Precise positioning and alignment of car seats

- Reduction of human error during installation

- Integration with other automated systems for seamless operation

- Enhanced speed in manufacturing processes

- Ability to perform repetitive tasks without fatigue

- Application of consistent pressure for secure fittings

- Data collection for monitoring and optimization

In today’s competitive automotive landscape, understanding how GAC Trumpchi uses robotics in car seat installation is pivotal. Through these robotic arms, the assembly line can operate more efficiently, accommodating the complexities of modern vehicle production. The critical advantage lies in the robotics’ ability to adapt and improve over time, learning from integrated systems data to optimize performance continuously.

Applications in Car Seat Installation

The applications of robotic arms extend far beyond simple tasks; they are capable of performing intricate installations that require high precision and care. The automated car seat fitting process not only enhances the speed of assembly but also ensures that each seat meets strict quality standards. By incorporating technology, GAC Trumpchi elevates the car interior assembly process, providing customers with seats that are not only well-installed but also ergonomically optimized for comfort.

Comparison of Traditional vs. Robotic Methods

When comparing traditional car seat assembly methods with modern robotic techniques, several key differences emerge. Traditional approaches often involve manual labor, which can be inefficient and prone to errors. In contrast, robotic methods streamline the installation process, enabling quicker setups and reduced labor costs. Overall, automotive robotics such as those used by GAC Trumpchi exemplify a shift toward a more efficient, reliable, and safe manufacturing environment, affirming the role of robotics in shaping the future of the automotive industry.

Advantages of Automated Car Seat Installation

The integration of robotic arms in car manufacturing has significantly transformed the way automotive companies approach various assembly processes, particularly GAC Trumpchi and its innovative methods for car seat automation. With the adoption of automated systems, GAC Trumpchi is not just enhancing the efficiency of car seat installation but also setting high standards for quality control and precision. This technology, commonly referred to as robotic car seat installation, enables the company to ensure that each seat meets rigorous safety and quality requirements.

Utilizing advanced robotics means that GAC Trumpchi can conduct automated car seat fitting with unmatched accuracy. By employing highly specialized robotics, the company minimizes human error, ensuring that every seat is installed correctly. This is crucial not only for comfort but also for the safety of passengers who rely on precise seat positioning during an accident. Furthermore, the implementation of such technology allows GAC Trumpchi to streamline its overall manufacturing processes, leading to more efficient vehicle assembly.

- Improved installation accuracy

- Reduced labor costs

- Enhanced safety standards

- Optimal use of manufacturing space

- Faster production times

- Consistency in quality

- Lower production defects

As it stands, the advantages of GAC Trumpchi’s automated approach extend beyond mere efficiency. The use of robotics in the vehicle assembly process also results in direct cost savings for the company, which can be pivotal in maintaining competitive pricing within the automotive market. The transition toward such sophisticated manufacturing solutions echoes the wider trends in automotive robotics, reflecting how essential precision and efficiency have become in the modern production landscape.

Direct Cost Savings

By leveraging advanced vehicle assembly robotics, GAC Trumpchi is positioned to realize significant direct cost savings. This paradigm shift also allows for more predictable budgeting in manufacturing costs, leading to both short-term and long-term financial benefits. The reduction in labor overheads, paired with decreased error rates, leads to lowered warranty claims and enhanced customer satisfaction. Ultimately, as the company continues to evolve its manufacturing process, it underscores a commitment to innovation and excellence in the realm of vehicle assembly.

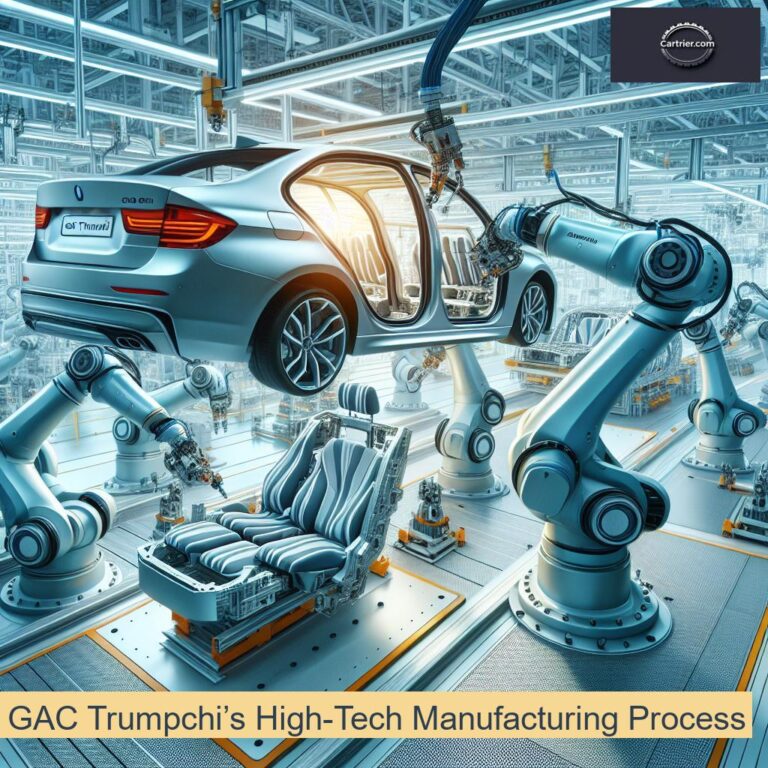

GAC Trumpchi’s High-Tech Manufacturing Process

GAC Trumpchi is at the forefront of automotive innovation, especially with its integration of robotic technologies in the manufacturing process. The use of robotic arms for precise car seat installation is a testament to how advanced manufacturing can improve efficiency and quality. By employing these technologies, GAC Trumpchi not only enhances the assembly process but also ensures that their GAC Trumpchi car seats meet the highest standards of comfort and safety.

Incorporating automotive robotics in their production lines allows GAC Trumpchi to achieve unparalleled precision in car interior assembly. The automated systems streamline the fitting process, reducing manual errors and ensuring consistent quality across all vehicles. The advancements in car seat automation mean that every seat is fitted precisely, thereby enhancing the overall vehicle integrity and customer satisfaction.

Steps in GAC Trumpchi’s Manufacturing Process

- Design and engineering of car seats.

- Material selection for durability and comfort.

- Robotic arm setup for seat assembly.

- Automated fitting of seat components.

- Quality assurance checks after installation.

- Final inspection and testing of interior.

- Packaging and preparation for shipment.

Through its commitment to harnessing advanced technologies, GAC Trumpchi has set the stage for improved manufacturing capabilities.

By using robotics, GAC Trumpchi ensures not just precision but also a significant reduction in production time, which ultimately benefits the end consumer.

This level of automation not only supports the company’s goal of increasing output but also aligns with industry trends towards greater efficiency and higher product consistency.

Integration of Robotic Technologies

The integration of robotic technologies into the GAC Trumpchi manufacturing process highlights a shift towards smarter production methods. This innovative approach allows for seamless coordination between multiple robotic devices, enhancing the vehicle assembly robotics ecosystem. As a result, the use of robotic arms in car manufacturing plays a significant role in eliminating manual labor, allowing workers to focus on quality control and oversight rather than repetitive tasks.

Quality Control Measures

Quality control is a fundamental component of GAC Trumpchi’s high-tech manufacturing process. Robust measures have been established to ensure that automated car seat fitting meets stringent industry regulations. Advanced sensor technologies are integrated into the robotic systems, allowing real-time monitoring and adjustments during production. This dedication to quality not only protects the brand reputation but also reinforces consumer trust in the reliability of GAC Trumpchi car seats.

Precision and Efficiency in Car Interior Assembly

In the rapidly evolving landscape of automotive manufacturing, GAC Trumpchi stands out by integrating advanced technologies to enhance car seat assembly. The use of robotic arms for car seat installation showcases a paradigm shift that not only ensures precision but also significantly boosts operational efficiency. When discussing GAC Trumpchi car seats, it becomes evident how robotic car seat installation offers a variety of benefits that ultimately streamline the production process while maintaining high quality.

As car manufacturers face increasing demand for quality and efficiency, GAC Trumpchi has embraced car seat automation through the adoption of automotive robotics. By employing robotic arms in car manufacturing, the organization guarantees that every car seat is installed with meticulous attention to detail. This level of precision minimizes human error and ensures consistency across all vehicles produced. The combination of robotics in vehicle assembly not only increases speed but also enhances the overall safety of the manufacturing process.

- Increased speed of installation processes

- High accuracy in seat fitting

- Reduction in production waste and errors

- Enhanced worker safety due to reduced manual handling

- Consistency across the production line

- Lower labor costs in the long term

- Ability to adapt to changing models or designs

Furthermore, automated car seat fitting allows for the handling of complex designs that would be challenging for manual labor. GAC Trumpchi’s manufacturing process effectively employs robotic arms to ensure that every seat is precisely aligned and installed according to the manufacturer’s specifications. This approach not only enhances the efficiency of the entire assembly process but also allows for greater innovation and adaptability to new designs in automotive interiors.

Importance of Precision

The significance of precision in car interior assembly cannot be overstated. A well-installed car seat is crucial for driver and passenger safety, which is a top priority for GAC Trumpchi. Utilizing robotics ensures that every installation meets stringent safety standards, thereby enhancing the overall value of the vehicle. By focusing on accurate measurements and careful execution, GAC Trumpchi leverages robotic technology to accomplish what traditional methods cannot, delivering a superior product that satisfies consumer demands and regulatory requirements alike.

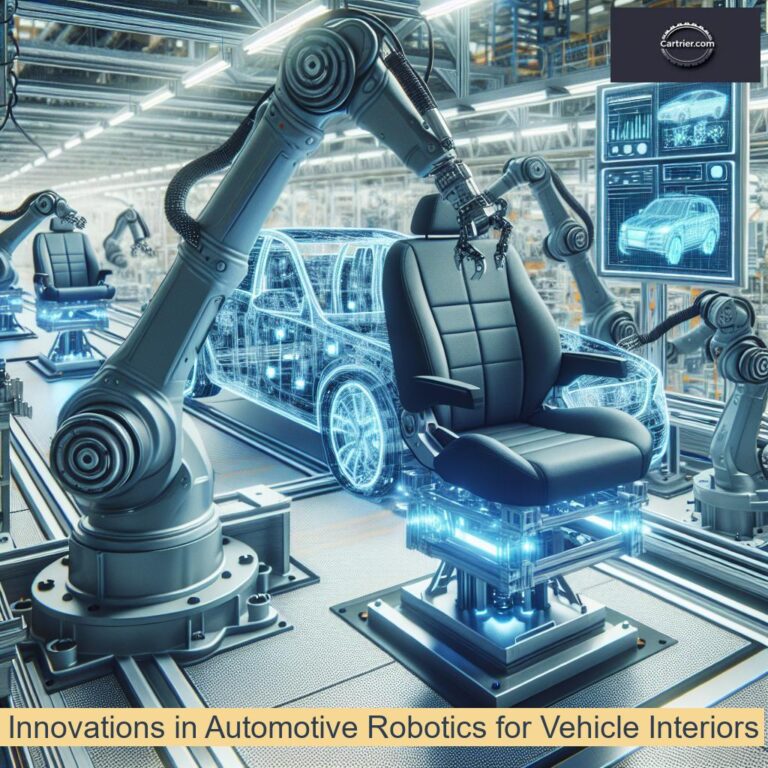

Innovations in Automotive Robotics for Vehicle Interiors

The integration of robotics in car manufacturing has notably improved processes, particularly in areas like GAC Trumpchi where efficiency and precision are paramount. One of the standout advancements has been in robotic car seat installation, which has evolved to become a model of innovation in the automotive sector. The seamless installation of GAC Trumpchi car seats illustrates how automated solutions can enhance both quality and effectiveness in vehicle assembly.

To understand how GAC Trumpchi employs advanced mechanical systems, it’s essential to delve into the components of their manufacturing process. The utilization of robotic arms in car manufacturing allows for unparalleled precision when fitting car interiors. This is not just about speed; it reflects a commitment to quality control, reducing the risk of defects and ensuring consumer safety in the final product.

Through cutting-edge technology, GAC Trumpchi has revolutionized the traditional methods of vehicle assembly, particularly in car seat automation.

Recent Innovations

- Advanced robotic arms for precise car seat fitting

- AI-driven quality control systems

- Enhanced sensors for real-time adjustments

- Collaborative robots that work alongside human operators

- Customizable assembly lines for different car models

- Predictive maintenance technologies for robotic systems

- Integration of VR for training robotic operators

Emerging Technologies

The future of automotive robotics continues to expand, driven by emerging technologies in artificial intelligence and machine learning. Innovations such as real-time data analytics enable systems to adapt and improve during the car interior assembly process. With continuous upgrades, companies like GAC Trumpchi are setting new benchmarks in automated car seat fitting, aiming for seamless production with minimal human interference. This revolution not only increases production rates but also enhances the reliability of the end product.

Future Trends in Robotic Car Seat Installation

As the automotive industry continues to adopt advanced technology, GAC Trumpchi is at the forefront of leveraging robotics for superior car seat installation. The integration of robotic arms into the GAC Trumpchi car seat assembly process has revolutionized how vehicle interiors are constructed. These automated systems not only enhance precision but also significantly boost production efficiency, marking a pivotal shift in car seat automation.

The implementation of robotic car seat installation minimizes human error and increases the overall quality of the assembly process. With robotic arms performing repetitive tasks, GAC Trumpchi can ensure that every car seat is installed accurately, thus improving safety and comfort for the end user. Furthermore, the ability to quickly adapt to different vehicle designs allows for expanded production capabilities, which is vital in today’s competitive market.

Anticipated Developments

- Increased use of AI and machine learning for real-time adjustments in seat fitting.

- Enhanced collaboration between robotic systems and human workers.

- Development of more flexible robotic arms to handle various seat models.

- Longer maintenance intervals for robotic systems, resulting in reduced downtime.

- Integration of sensors for better quality control during installation.

- Expansion of automation technology to other interior components.

- Enhanced traceability of installation quality through data analytics.

The future of GAC Trumpchi and its robotic arms in car manufacturing looks promising. As the reliance on automotive robotics increases, the company is expected to spearhead innovations that not only streamline vehicle assembly robotics but also improve the convenience of automated car seat fitting. This transition aims to enhance the overall driving experience, aligning with consumer demands for higher quality automobiles.